White paper on artificial intelligence on the shop floor

Over the years artificial intelligence (AI) has evolved in its capabilities and found innumerable applications in the field of industrial automation. While adoption is still slow, the researchers Frost & Sullivan (F&S) confirm in a new white paper that there will be no limit to what AI can achieve across the multitude of industrial sectors and functions.

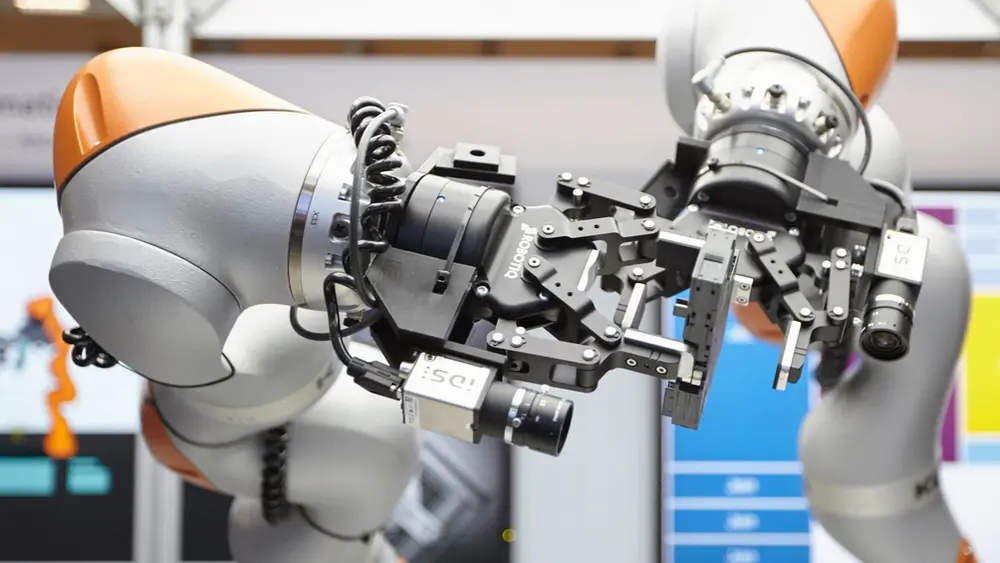

Machines that learn from their own experiences

The benefits of AI will be derived across product, process, and strategic levels of manufacturing. With AI, machines will no longer require specific programming to perform tasks. Instead, they’ll have the potential to learn from their own experiences. Companies can make use of data and related digitalization technology to not only improve their own business but also to transform the entire industrial ecosystem.

In the new white paper 'Artificial Intelligence in the Shop Floor' the F&S researchers highlight the capabilities of AI and also profile the yin and yang of AI in industrial automation. The “Big 5 Areas of Concern about AI” are followed by a risk-reward analysis. AI, the researchers say, enables manufacturers all over the world to quickly innovate, adapt, and respond to the evolving needs of their industries without compromising cost and quality.

Among the key benefits of AI, the white paper cites less manual effort, fewer errors, more picks per hour, faster time-to-market, and self optimization of processes. The paper also identifies automation hot spots for AI on the factory shop floor, like self-programmable PLC, enhanced collaboration, and autonomous optimization.

Download the white paper.